03 - RCD Protection and Selection for Packaging Machines

Do Users comply with essential safety requirements when they install and use packaging machines containing VSD associated with RCCBs!

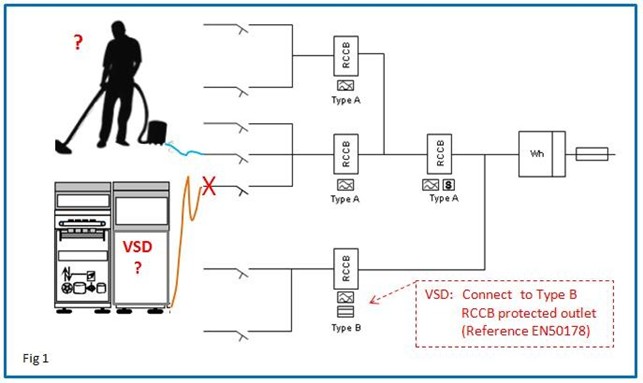

Packaging machines containing frequency inverters for speed control connected via cable and plug to a mains distribution socket protected by a standard RCCB, may not meet the requirements of the Electricity at Work Regulations (EWR). In addition untrained support staff using electrical appliances connected to sockets on the same distribution circuit may also be put at risk. See Fig 1

Fig 1

EWR 4 places a duty of care on the Duty Holder with regard to the Electrical Systems and the components making up that system: Regulation 4(1) 65 The safety of a system depends upon the proper selection of all the electrical equipment in the system and the proper consideration of the inter-relationship between the individual items of equipment.

RCCB Protection with VSDs

To comply with Regulation 4(1) 65 - Where the precautions taken include an RCCB to reduce the risk of death or injury (Regulation 8), the RCCB must be suitable for use with VSDs. The Duty Holder to comply with current laws on H&S must make reference to the VSD manufactures recommendations relating to the type and characteristics of the RCCB required. If this is not clearly stated in the operating instruction, obtain the manufactures recommendations in writing. Depending on the topology of the VSD and certainly with 3 phase units it would not be safe to use an AC or A Type RCCB.

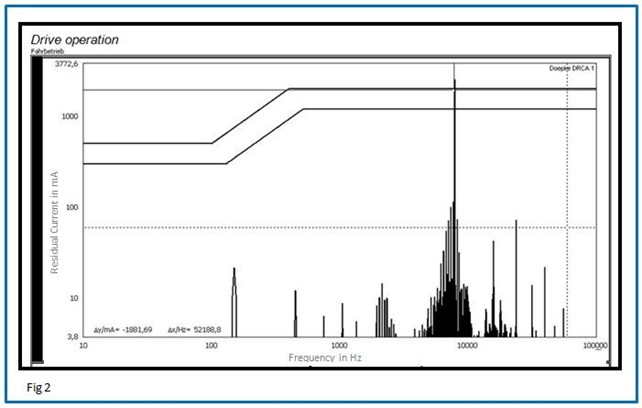

AC operational leakage currents: 3 Phase Inverters used for speed control and the associated EMC filters and motor cables, generate leakage currents at nominal supply frequency (50Hz) and at various harmonic frequencies. Leakage currents in the higher frequency ranges can be significant and from a safety perspective cannot be ignored, as can be seen from the following example. Figure 2 shows the frequency range of various leakage currents present in a system containing a 32 amp VSD; at 50hz the leakage current is less than 3mA, however the actual maximum leakage current occurs at 7815 Hz and is approaching 2000mA. This installation had to be taken out of service by the user, and the Drives Manufacture contacted to look at ways to reduce the leakage currents to meet fire protection requirements of 300mA for this site. Fortunately for the user, the standard RCCB they tried to use in the installation tripped on start up due to the inrush current associated with the EMC filter capacitors. Also it is worth remembering that standard RCCBs are only designed to operate at the nominal supply frequency, for example 50Hz in the UK. The Duty Holder in this instance did not just by-pass the RCCB or fit a time delay unit to try and get around the problem, he had the system checked. Basic electrical test instruments do not give a complete picture of the leakage currents present under normal operation.

Fig 2

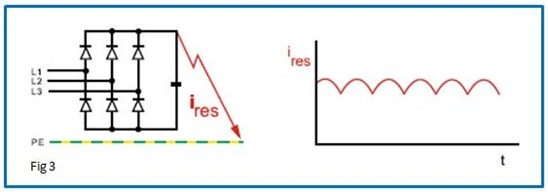

DC Residual Currents: Under certain fault conditions 3 phase inverters produce smooth DC residual currents (see fig 3), which would not trip a conventional RCCB. In addition this DC current produces magnetic saturation within the AC trip coil, resulting in a change to the designed trip characteristics for sensing AC residual currents flowing through standard RCCBs. A product applied outside of its original design tolerance cannot be and should not be relied on to perform a safety function, covered under IEE wiring regulation clause 133.1.3

Fig 3

Safe application of VSD’s using B Type RCCBs

The Electricity at Work Regulations makes reference to the IEE Regulations as a guidance document (unless the site is specifically covered by another code of practice such as Mines & Quarries), existing Regulation 331.1 is quite clear in its requirement “An assessment shall be made of any characteristic of equipment likely to have harmful effects upon other electrical equipment”. A simple assessment carried out under Regulation 331.1 in accordance with existing Health & Safety legislation, on a system containing VSDs and requiring RCCB protection, will quickly identify that you cannot use conventional a RCCB, and that a B Type RCCB must be used with a characteristic compatible with the operational and safety requirements of the installation for People and or Fire protection. To safely commission an installation containing a VSD follow the manufactures instructions. Use a residual current analyzer (such as DRCA1) to determine the actual maximum level and frequency of the leakage currents present in the installation; leakage current at 50Hz, maximum leakage current and the frequency it is generated at, the maximum frequency and leakage current. These values will change based on the drive status / Power on VSD off / VSD ramping up / down etc. Having this information available will enable the engineer to validate the RCCB selection, reducing the risk of nuisance trips, but more importantly make certain that the RCCB is selected correctly for the safety requirements associated with the installation.

Chaz Andrews – Technical Manager, Doepke UK Ltd

© 2018-2020 Chaz Andrews – Technical Manager, Doepke UK Ltd. All Rights Reserved. Doepke Tec Art 03 VSD PB article V1 14th Sept

If you would like more detailed information relating to this subject, Doepke UK have a free 60 page Technical Application Guide Available on request, or visit our website to download the guide or obtain further information on RCCBs.