15 - RCD Protection and Selection for Green Buildings

Green Technology - RCD Specification

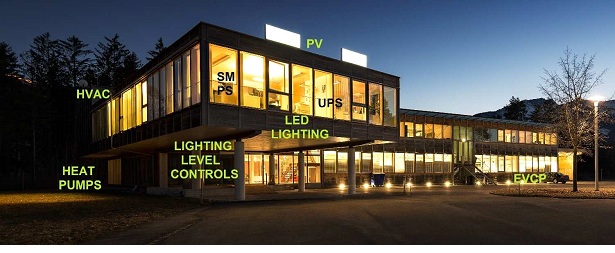

Domestic, commercial and public buildings designed to meet the latest energy standards can contain a range of energy saving devices and technology from simple LED lighting, appliances with built-in inverters to more complex ground source heat pumps.

These devices cannot be used with standard AC RCDs and this must be taken into account when specifying, designing and completing the installation. A number of applications are not covered in specific detail in existing guidance, so great care must be taken to reduce the risk of electrocution and fire when selecting RCDs.

Why does the load affect the RCD selection?

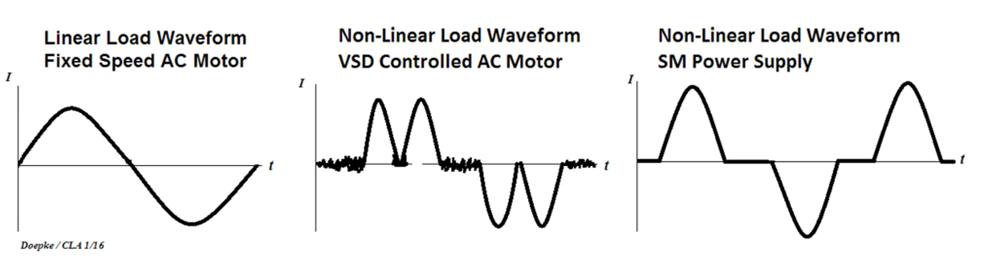

Energy saving technology relies on power electronics to alter and or chop the electrical supply i.e. producing non-linear load characteristics. Type AC RCDs can only be used with loads that generate sinusoidal leakage and residual currents (linear loads) see Fig 1. Inverters used in lighting control, speed control and power supplies produce complex leakage and residual currents affecting the tripping characteristics of standard AC RCDs. This phenomenon associated with magnetic saturation of the trip circuit, is commonly referred to as “RCD Blinding”.

Fig 1 Type AC RCDs can only be used with loads that generate sinusoidal leakage and residual currents (linear loads)

The risks associated with incorrect RCD selection

RCD’s are installed to provide “Additional protection” and or “Fire protection”, when a primary protection method fails. Ensuring they work when called on to do so, could mean the difference between life and death.

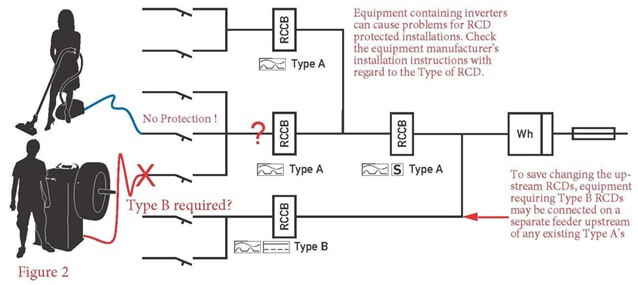

Installing equipment on a circuit protected by the incorrect type of RCD, will compromise the protection levels and safety for staff using other equipment connected to the same circuit. See Figure 2

The Electrical Safety Council have estimated, that around 2.5 million people receive an electric shock each year, of which 350,000 receive a serious injury. Even persons with electrical knowledge do not always fully perceive the risks associated with electricity. The Electricity at Work Regulations make it clear (EWR 2.35); “You should always consider the conventional public electricity supply voltage of 230 V ac as potentially fatal”.

Those involved in Specification, Design and Installation, Employees or Self Employed have a duty of care under the Health & Safety at Work Act 1974. Companies should take note of the new sentencing guidelines issued by the Sentencing Council in February 2016, relating to breaches of H&S Regulations.

Fig 2 RCDs installed to provide protection

Existing guidance relating to RCDs – is it clear enough?

Health & Safety at Work Regulations and the Electricity at Work Regulations 1989 (EWRs) reflect legal obligations as compared to non-statutory codes of practice such as the Wiring Regulations (BS7671), which only give advice. This relationship is important when making decisions relating to circuit design and selection of RCDs, for applications where the nature of the equipment connected in circuit could affect the safety performance of the RCD.

BS 7671 details minimum safety requirements, traditional aimed at improving safety through non-statutory regulation in domestic and similar premises. This may not be sufficient in commercial and or industrial environments, when considering the safety of employees and customers. In the event of an employee or customer receiving an electric shock from a 230V supply (potentially fatal in all instances), just meeting the Wiring Regulations may not prevent prosecution in the event of a breach of a Statutory Regulation.

HSE Guidance HSR25 3rd Edition Oct 2015(EWRs) – Regulation 16 places a duty of care on Employers “No person shall be engaged in any work activity where technical knowledge or experience is necessary to prevent danger or, where appropriate, injury unless he possesses such knowledge or experience…. “. Likewise individuals must not put themselves at risk or others as a result of their actions. If you are not sure check and seek further advice from your manager, the equipment manufacture and or trade association.

For example BS7671 Regulation 331 Compatibility of Characteristics, covers the “assessment of characteristics of equipment likely to have harmful effects upon other electrical equipment in the installation”. There are some specific examples given in BS7671 (see Part 7) where Type AC RCDs are not suitable, but this does not cover all the possible applications. An obvious example would be the connection of 3 phase VSDs /inverters into a circuit which has Type AC or Type A RCD protection upstream. Although it is not specifically stated in BS7671, we all know it is not safe to use 3 phase VSDs with anything other than a Type B RCDs.

However, there are many applications where it is not so obvious and 331 is there as “catch all clause”. When installing any new equipment either fixed, portable or transportable, where RDC protection forms part of the “Risk Reduction Measures”, the Risk Assessment must include a review of the existing installation and proposed RCD protection to ensure it is appropriate.

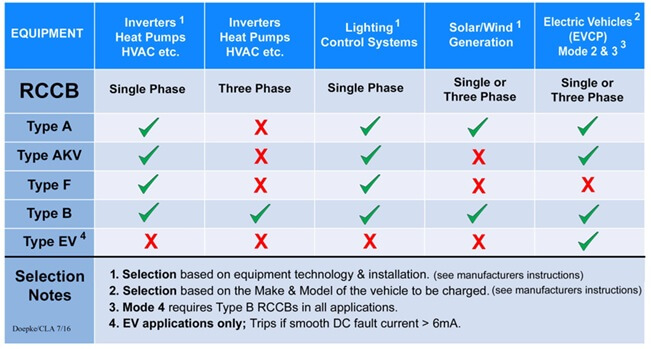

Equipment Requiring Special Types of RCD (RCCB) - Table 1

The table below gives some generic examples based on the installed technology used and the associated RCCB. It is imperative that the Equipment Manufactures Installation Instructions are checked, with regard to advice relating to the minimum sensitivity and the Type of RCD that can be used safely with their equipment. If the manufacture does not give any installation advice relating to the connection of their equipment to an RCD protected circuit, don’t assume it is safe to connect to any old RCD! Check with the manufacturer and include their response in the Design and Risk Assessment Documentation. Be wary of manufactures who do not appear to understand what or why you are asking these questions and also instructions provided with equipment manufactured outside of the EU, which may not reflect UK H&S Safety Requirements. Table 1

Table 1 Equipment requiring special RCDs

RCCB Checklist / General Limits of Operation - Table 2

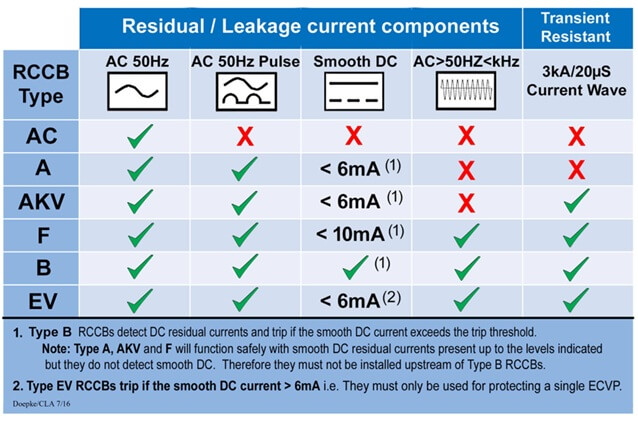

Understanding the different Types of RCCB and the characteristics that may be specified by equipment manufacturers, reduces the risk of installing inappropriate and unsafe protection. In addition it also helps during risk assessment for existing installations, to identify potential dangerous situations and installations. RCCBs are designed and calibrated to operate in the presence of specific types of residual current, basically the greater the complexity of the residual current flowing under fault conditions, the more complex the design of RCCB required to detect those currents.

Operational leakage currents for nonlinear loads can be significantly higher than conventional equipment, and must be taken into account when designing the installation. RCCB tripping current (sensitivity) must be selected based on the operational leakage currents, and the load circuits’ sub divided if necessary to prevent unwanted tripping i.e. leakage currents must be added together for each item of equipment connected to the RCCB – see regulation 531.2.4

Table 2 Residual current leakages

For more detailed information on specific applications relating to RCCB selection, please refer to Doepke Web Site – Technical Articles and our RCCB hand book.

Chaz Andrews – Technical Manager, Doepke UK Ltd

Note: Article 1st published in the ECN Magazine June 2016 under the heading Current Account – RCD Specification

SOURCE: © 2018 - 2025 Chaz Andrews. All Rights Reserved. Ref: RCD Safety and Green Technology July 16v2