26 - Residual current protection or residual current monitoring?

Chaz Andrews Doepke Technical Manager – Outlines key differences between RCMs and RCDs. This article is aimed at Staff on commercial and industrial sites who have a limited knowledge of BS7671 requirements.

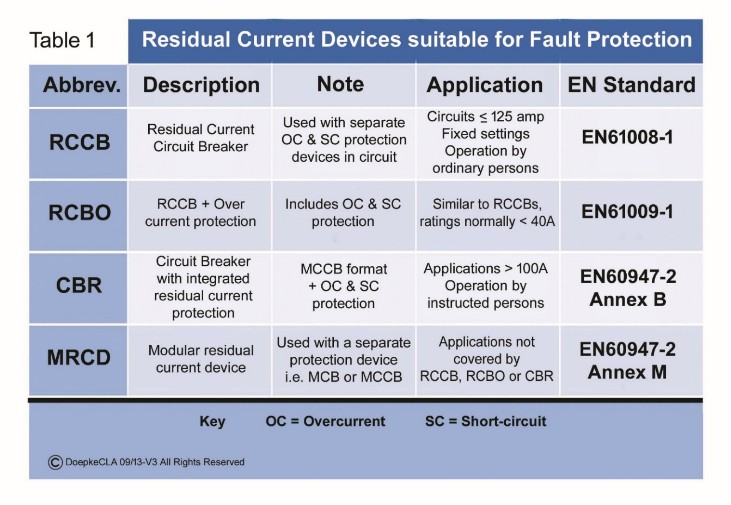

RCDs (RCCB, RCBO, CBR, MRCD) as defined in BS7671 and summarized in Table 1 below, disconnect and isolate a circuit when the residual current * exceeds a predefined value. The sensitivity of the RCD (milliamps) and its time / current characteristic (milliseconds) determine the protection level. Conversely an RCM is designed specifically for monitoring purposes – see BS7671 clause 4.11.

* Residual Current = Algebraic sum of the currents measured at a point in an electrical circuit.

RCD Standards

RCCBs and RCBOs can be used in installations operated by ordinary persons. CBRs and MRCDs are for operation by instructed / skilled persons – see BS7671 clause 531.3.4.1. RCD sensitivity and tripping time requirements are given in BS7671 based on the required protection level namely, Additional, Fire or Fault protection and the system earthing. Annex A53 specifies the general product standards for RCDs see table 1.

RCM Standard

EN62020 allows RCM actuating time < 10 seconds at the rated residual current. Consequently, RCMs cannot provide protection in TN or TT installations. Specific rules apply to RCMs used in IT systems - under the permanent supervision of skilled or instructed persons.

RCMs are designed for monitoring, providing pre-alarm and alarm status. Th is enables remedial action in situations where the unexpected tripping of an RCD would create a hazard (hospital, public place...) or production stoppage (manufacturing, process industry…).

Note: RCM installed downstream of RCD; set the RCM at < 0.5 x RCD sensitivity to reduces the risk of the RCD tripping before the RCM - refer to BS7671 clause 538.4.

Circuits that are permanently monitored by an RCM do not require periodic insulation resistance testing, providing the RCM is regularly checked using the trip test feature – see BS 7671 651.2

Types of residual current

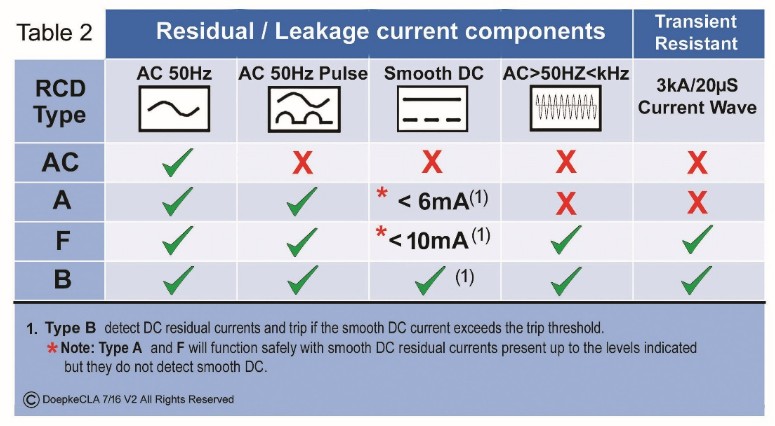

All AC loads produce leakage (PE) currents at mains frequency and harmonic frequencies. Take this into account to avoid unwanted tripping – see 531.3.2. Under fault conditions some loads produce pulsed or smooth DC residual current components. The RCD or RCM “Type” (see table 2) must be suitable for the PE and residual currents that it could be exposed to – see BS7671 clause 531.3.3.

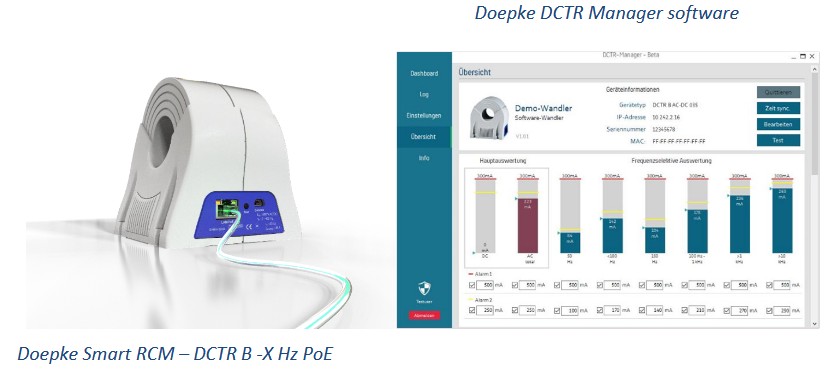

The Doepke smart residual current monitor provides an overview of a system’s residual-current status inclusive of all frequency ranges from 0 to 100 kHz, enabling the setting of specific parameters. Installation is quick and simple with just one connection via a PoE port, for basic functionality using DCTR Manager software.

The DCTR Manager software enables customised display of the system’s residual current status for single or multiple units, with emailing of alarm status and scheduled customised reporting as required. Constant monitoring of residual currents via a smart DCTR provides information about the system’s leakage current status, for reporting purposes e.g. maintenance records to meet PUWER and EWR requirements, which may require additional tests.

The DCTR B-X Hz PoE is a type-B residual current monitor suitable for use in systems containing VSD, VFD and other inverter based products. The monitoring concept can be adjusted for the system, depending on the application. In addition two signal contacts can be configured to operate on pre-set values e.g. trigger a visual or acoustic alarm or switch off the system.

Conclusion

Based on the average hourly cost for system downtime, the investment in a DCTR smart monitoring system can be easily recovered, with the prevention of one unplanned shutdown and the associated production losses.

Chaz Andrews – Technical Manager, Doepke UK Ltd

SOURCE: © 2020 - 2023 Chaz Andrews. All Rights Reserved. Doepke Tec Art 26 RCD or RCM v1 Junel 2021