31 - BS7671 Amendment 2 - 722 Mode 3 chargepoint standards?

BS7671 Amendment 2 - 722 Mode 3 chargepoint standards?

EV Installers are responsible for checking that equipment and products they install in the UK, meet the appropriate product standards and the requirements of BS7671, before they sign-off the Installation.

In principle this should be straightforward, but in practice this can be a complex process. Reviewing the chargepoint documentation and information provided on manufacturer’s websites and then relating this to BS7671, requires a clear understanding of the requirements of BS7671: Reference design, Installation and Testing.

The more we understand about a subject, the quicker we can reach informed and safe conclusions.

Documentation?

Installers can protect themselves by following the exact requirements of BS7671 relating to design, install, inspection and testing. With the appropriate knowledge and experience, decisions can be made quickly and effectively, when reviewing manufacturers documentation.

Recognising the main subject heading of the standards referenced in BS7671, associated with RCD protection and EV chargepoints, is a prerequisite to knowing what to look for when selecting chargepoints. Put simply, the more features proposedly offered by the chargepoint manufacturer – the greater the focus required on the manufacturer’s small print, relating to the standards they claim to meet. BS 7671 states clearly which products standards must be met, regarding the products used to provide for example “Additional Protection”.

BS 7671 Regulation 133.1.1 refers to "Appropriate Standards"?

An appropriate standard is one that has been adopted in BS7671, as providing the basic recognised safety requirements for associated subjects or products. See summary notes on Page 4 and 7 and Regulation 511. Appendix 1 provides a complete list of standards and the relevant edition / version referenced in BS7671 design requirements.

Accepting where no EN/IEC equivalent exists (e.g.,BS1363), the BS standard updating process will follow the EN standard with the addition of any UK national conditions. For example in BS EN 61851-1 2019 for the UK market clause 14C applies; ”30 mA chargepoint RCDs must be manually reset”. This aligns with the requirements in BS7671 531.1.1: Auto resetting RCDs cannot be used in installations accessible by ordinary persons.

In the absence of an EN standard, the BS standard may be based on the IEC standard, e.g., BS IEC 62955 RDC-DDs used in Mode 3 chargepoints: Reference BS7671 722.531.3.101 and BS EN 61851-1 8.5. For a free overview of the standards referenced in BS7671, refer to the BSI website.

Declarations of Conformity may refer to different versions of a standard – Why is this?

Before we discuss this, keep in mind that D of C are issued to meet market surveillance / customs requirements. These documents do not provide technical design and application details. To demonstrate presumption of conformity Manufacturers normally test to designated standards*, i.e. to meet customs requirements relating to free movement of goods, manufacturers based in Europe issue CE D of C based on EN standards.

D of C for equipment already in the market (e.g. at Wholesalers), may refer to earlier versions of the associated standards i.e. the declaration relates to the equipment design, when it was first placed on the market. BS 7671 Reg 133.1.3 requires that such equipment provides the same degree of safety as equipment that meets the current standards. For example, the BS7671 722 2018 update included the reference to 6 mA DC detection: Installers purchasing mode 3 chargepoints for use with Type A RCDs, had to verify inclusion of 6 mA detection feature in the chargepoint or make alternative arrangements within the design of the installation.

* Designated standards are listed on the UK Gov website for UKCA** Marking purposes or the EU equivalent (OJEU) for CE Marking. Lists of designated standards may or may not align with the BS7671 publication / amendment when it goes to print. Testing to a designated standard to demonstrate compliance with an associated Directive /Regulation is at the discretion of the manufacturer / importer.

Choosing another route to demonstrate compliance, would place the manufacturer at a significant disadvantage to other competitors, who do meet the standards. See BS7671 133.1.3 and OZEV minimum technical specifications for charging equipment relating to BS Standards.

D of C cannot be used in isolation to verify the appropriateness of electrical equipment- see Reg 642.2 indent (i) & (ii). Refer to the manufacturer’s installation documentation, specifically comments relating to UK application and the requirements of BS7671. Small but critical safety points, such as the use of non-auto retting RCDs must be considered during design and when commissioning equipment.

**1st August 23: The UK Government intends to extend indefinitely acceptance of CE Marking for majority of equipment sold in the UK. This includes electrical equipment covered by the Low Voltage Directive.

Is it an RCD as defined by BS7671?

30 mA RCD protection built into mode 3 chargepoints: BS7671 722.531.3.101 specifies that RCD protection must meet specific standards (discussed in detail below). Ambiguous claims regarding protection built into chargepoints, could lead to the Installer making false declarations on the associated installation certificates. Worse, this may provide ineffectual protection for users of the chargepoints.

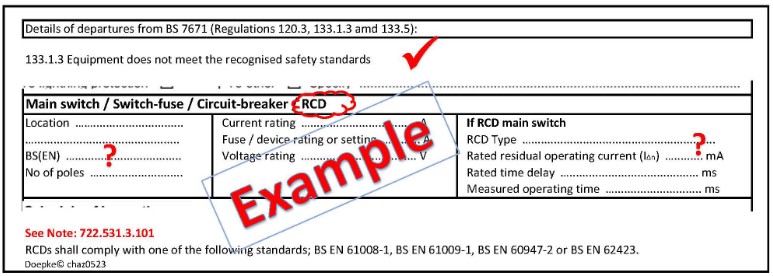

The section in the installation certificate relating to RCD protection, refers to RCDs that meet the standards specified in BS7671: Any departures from BS7671 e.g. using products that do not meet the standards must be recorded separately – see 120.3, 133.1.3, 133.5. Note the requirements of Reg 133.1.3: Append a declaration to the test certificate giving full details of the deviations and why i.e. BS7671 requires that “… the equipment provides the same degree of safety as that afforded by compliance with the Regulations.”

In practice an Installer would be ill-advised to take on the responsibility for the design performance of equipment that does not meet the applicable standards - see Reg. 133.1.1.

Inspection, Testing & Installation Certificates.

Verifying that the product is safe for use in accordance with BS7671:

642.1: This inspection clarifies that the equipment and the installation conform to the appropriate standards for the UK. Checking the electrical equipment specifications before it is installed, saves time and money.

642.2: Verify the requirements of 511; namely every item of equipment shall comply with current appropriate standards listed in BS7671. Verified by reference to the manufacturer’s current documentation relating to use in the UK.

There is a risk that EV equipment that is already in the supply chain could be out of date and or subject to modification, such as a change to the installation instructions. Technical information on an intermediary’s website may not be up to date. Have you got access to the manufacturer’s current documentation. Has the manufacturer made any changes, which affect the installation design?

133.1.1: An RCD installed in the chargepoint be it a product or integrated function, must meet the full requirements of 61008, or 61009 as appropriate. Check the chargepoint documentation and small print to verify the RCD function meets the correct standards. Manufacturers who do not meet the standards, should state clearly that an additional RCD must be installed in circuit to meet 722.531.3.101. If in doubt, fit an external RCD to the appropriate standards required by BS7671.

For those of you who are new to the industry, be aware that info shared on YouTube may not be accurate. For example performing a simple RCD tripping Test to 643.7 on the output of a black box, does not prove that the box contains an RCD. Verify by following the correct inspection procedure detailed in BS7671, as you would with any consumer unit. A mode 3 chargepoint is effectively a consumer unit with a socket or cable attached to it, plus a bit of electronics for controlling the charging communication / function.

BS7671 722.531.3.101 RCD or RDC definition?

Understanding the basic terminology associated with EV charging, is a prerequisite to making informed and safe decisions regarding equipment.

As with RCDs, RDC-DDs (Residual Direct Current Detection Devices) are classified according to their functionality. The acronyms RCD and RDC-DD are similar, but their functions are different and can easily be confused by the unwary or inexperienced.

RCDs: Provide fault protection and additional protection as defined in BS7671 – RCDs are normally associated with fault currents in the mA range. However, RCD contacts in combination with short circuit protection (internal or external to the device), must open safely and electrically isolate the circuit when subjected to any fault current, up to the breaking capacity of the combination.

Referring to RCDs as “Electronic” as opposed to “Electro-mechanical” displays a limited knowledge of RCD technology. Any Type A RCD used in association with EV charging applications will contain electronic components, and all RCDs must use electro-mechanical contacts to provide galvanic isolation.

The standards classify RCDs as fault breaking devices; the contacts and chambers must be designed accordingly, to handle a specified range of fault currents safely and reliably without welding. Isolation contact gaps for RCDs are greater than those required for small contactors and PCB mounted relays, used in EV chargepoint designs. Short circuit breaking tests required by the RCD standards (61008 or 61009), verify that the circuit is electrically isolated following a fault. Doepke and other reputable RCD manufacturers have their devices certified by 3rd parties such as VDE.

BS7671 specifies that RCDs used in UK installations must meet one of the following standards 61008, 61009 or 60947-2. This also applies to EV chargepoints – see 722.531.3.101.

RDC-DD: The primary function of an RDC-DD (BS IEC 62955) for use in Mode 3 charging applications, is to detect low values of smooth DC fault current and disconnect the circuit. DC fault currents (fault currents with a time base < ½ cycle that do not pass through zero), saturate the induction technology used to monitor AC residual currents.

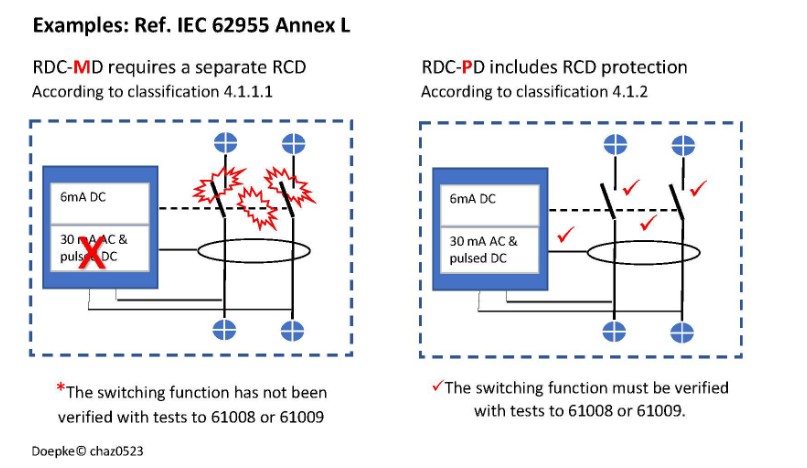

BS IEC 62955 defines two basic classifications of RDC-DDs: Namely RDC-MD and RDC-PD.

RDC-MD: The M stands for MONITORING.

RDC-MD: There are 3 sub classifications (forms of product configuration defined in the standard):

- RDC MD 4.1.1.1 see example diagram ref IEC 62955 Annex L

- RDC MD 4.1.1.2 (RDC MD mechanically coupled to RCBO /RCCB / MCB)

- RDC MD 4.1.1.3 (RDC MD electrically coupled to RCBO / RCCB …)

Example of an RCM used for detecting 6 mA DC in AC circuits. The chargepoint manufacturer is responsible for carrying out the product verification testing on the RDC MD 4.1.1.1 (combination of RCM + Switching device), to the requirements of BS IEC 62955 as required by BS7671-722.531.3.101.

Chargepoint manufacturers who do not test to the standards, cannot provide the verification specified in BS7671.

Example of an RCM used for detecting 6 mA DC in AC circuits. The chargepoint manufacturer is esponsible for carrying out the product verification testing on the RDC MD 4.1.1.1 (combination of RCM + Switching device), to the requirements of BS IEC 62955 as required by BS7671-722.531.3.101.

Chargepoint manufacturers who do not test to the standards, cannot provide the verification specified in BS7671.

BS IEC 62955 9.11.2.3 states that RDC-MD plus a SCPD (specified by the manufacturer), must be subjected to short-circuit tests. These tests verify that the RDC-MD+SCPD can withstand without damage, short-circuit currents up to the rated conditional short circuit current Inc. The combination shall be suitable for re-use after the tests i.e. the contacts must not weld, and the insulation voltage must be maintained. The minimum value of Inc allowed in the standard is 500A i.e. The prospective fault current at the point of installation, must not exceed the value detailed in the chargepoint specification.

The chargepoint standard BS EN IEC 61851-1 12.2 specifies that relays meet 61810-1 and or contactors meet 60947-4. These standards recognise the elevated risk of contact welding when applying these devices*. For example when subject to values of current above the contactor manufacturer’s quoted making capacity.

* To provide 30 mA protection, BS IEC 62955 specifies that RDC-MDs must be used in combination with an RCD conforming to 61008 or 61009.

RDC-PD: The P stands for PROTECTION.

Classification 4.1.2 devices in addition to 6 mA smooth dc detection, provide 30 mA residual current protection and isolation under fault conditions.

* Annex O of BS IEC 62955 states that the tests on the RDC-PD to the relevant RCD standard “apply without modification”. Conventional contactor or relay contacts would not pass the full test requirements of 61008 or 61009.

BS7671 722.511.101 EV chargepoints shall comply with the relevant parts of 61851-1:

Example:

Chargepoint design does not take account of the risks associated with the use of contactor or relay contacts in fault breaking applications i.e. not followed the recommendations in the standards. RCD not included in the circuit to provide additional protection as required by BS7671.

Think first – if this were your house, would you install a consumer unit with a two-pole relay, operated by a residual current monitor – in the place of a 2 pole RCCB – Without question – NO I do not think so!

Read the manufactures small print, before installing a chargepoint without the associated RCD protection required by the standards. Just imagine it is one of your family members handling a charging cable in the rain.

Standards referenced in BS7671 help Installers make reasoned and safe decisions:

The standards referred to in this article, allow for technical product developments incorporating basic electrical safety requirements. There is no excuse for not meeting basic electrical safety standards.

61851-1 Clause 8.5 specifies that RCDs used in the equipment shall comply with one of the following products standards 61008, 61009, 60947 -2* and 62423** for Type F or B if applicable i.e. the RCD is evaluated as a stand-alone device, to the appropriate standard.

61851-1 Clause 14 (C) UK only : 30 mA chargepoint RCDs must be manually reset i.e. they must not be automatically reset by the software in the chargepoint or remotely resettable i.e. reference BS7671 531.1.1; auto-reclosing of RCDs shall only be installed in locations where access is restricted to instructed or skilled persons only i.e. Chargepoints are accessed and operated by ordinary persons.

As explained earlier in the article, RDC-MDs that use conventional PCB relays or contactors for switching charging currents and low levels of smooth dc fault current, are not suitable for the provision of 30 mA RDC protection. They must be used with a separate RCD / fault breaking device that has been tested to 61008 or 61009. RDC-PDs incorporate 30 mA protection, but in addition to meeting BS IEC 62955 must also meet 61008 or 61009.

*60947-2 relates to CBRs: Not suitable for use by ordinary persons – see 411.4.4, Note 2

**62423 Type F or B RCD test characteristics: Additional tests required to 61008-1, 61009-1, 60947-2.

Conclusion

Chargepoint documentation, which pertains to provide RCD protection but does not make specific reference to the product standards specified in BS7671, may be hiding the fact that a separate RCD is required to meet BS7671.

Purchasing and installing non-conforming electrical equipment places the onus of responsibility on the Installer; ref 7671 133.1.3. In practice it would be impossible for an Installer to achieve this without access to a specialised design and testing facility, with appropriate design knowledge, standards, and test equipment.

Using recognised standards is a simple and safe way to verify the basic performance requirements, and the longer-term safety of equipment. These standards must be applied in full as appropriate to the safety of the equipment or product e.g. If the chargepoint manufacturer is claiming to provide 30 mA RCD protection, the RCD function must meet the associated RCD standard in full.

BS7671 specifies that chargepoint equipment must meet 61851-1 . These standards state that 30 mA RCD functions, used in or external to the chargepoint equipment, meet 61008 or 61009 as appropriate.

Chaz Andrews – Technical Manager, Doepke UK Ltd

SOURCE: © 2024 - 2026 Chaz Andrews. All Rights Reserved. Doepke Tec Art 31 BS7671 Amd 2 Mode 3 CP Standards v 4 Aug 2023.